Multi-turn actuators can be used for any type of application that requires high torque rotary movement. It can also be used on butterfly and gas valves with a gearbox up to the size of 1800 mm.

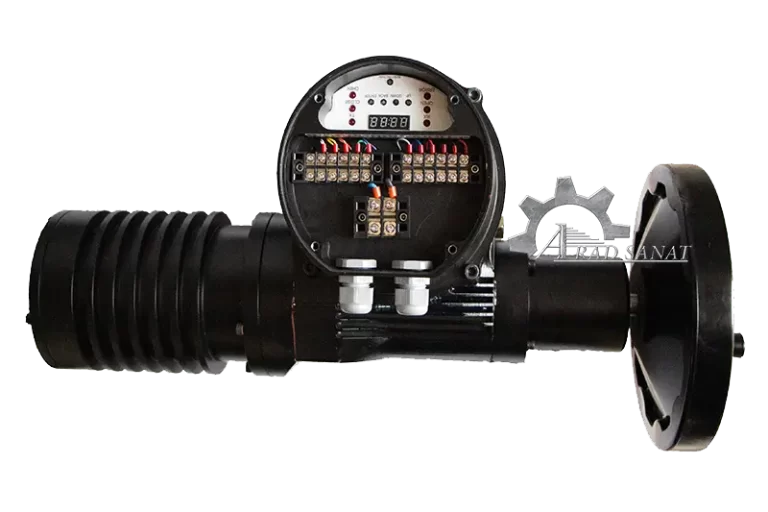

This electric actuator is multi-turn and can be adjusted up to 700 turns. The flange related to the coupling of multi-turn electric actuators on F14 and F10 type gearboxes is in accordance with the ISO 5211 standard.

Multi-turn electric actuators are produced with the highest level of quality. This type of actuator is completely waterproof and can be operated up to a depth of 5 meters under water.

These multi-turn electric actuators support the Modbus protocol or 4-20 mA for command. The motor used in this electric actuator is BLDC type with an efficiency of more than 88%.

Based on the example of large electric actuator manufacturers such as AUMA and ROTORK, Arad Sanat can produce multi-turn electric actuators with the same efficiency and quality.

These electric actuators were designed not only following the example of these two brands, but also adding creativity. Furthermore, this company’s electric actuators are made from the latest technology and motors that are of the highest efficiency (BLDC motors) in the world, making them a serious competitor for other world-class brands.

AM010 Electric Actuator

AM050 Electric Actuator

AM060 Electric Actuator

AM120 Electric Actuator

AM250 Electric Actuator

Multi-turn electric actuators are primarily used in fluid transmission lines (water, oil, etc.) and on all types of valves, including ball valves, butterfly valves, gate valves, and needle (Globe Valve).

These electric actuators are typically installed on large valves (generally 6 inches and above), so an auxiliary gearbox is required to increase torque and increase the number of turns.

Butterfly valves, for example, require the input of the gearbox to rotate several times for the valve to completely open and close (by turning the tab 90 degrees). As a result of this method, multi-turn electric actuators can be used as electric valves.

Some valves, such as sliding and needle valves, require not only the rotation of the shaft to open and close, but also the up and down motion of the shaft. This type of valve requires a special gearbox to neutralize the up and down movement of the valve shaft.

The auxiliary gearboxes are chosen based on the size and type of valves, and the actuators are also chosen based on the gearboxes. Electric actuators are determined by the input torque, input revolutions, and input flange type of a gearbox.

A gearbox’s torque is determined by its type, size, and ratio of valves; A butterfly valve, for example, requires 1200 Nm of torque to open and close (turning the blade 90 degrees), but a 1 to 40 gearbox can reduce this to 30 Nm. Therefore, when the input shaft rotates 40 revolutions, the output shaft rotates 1 revolution, and since the output shaft of the gearbox rotates 90 degrees when the input shaft is rotated 10 revolutions, the valve opens and closes when the output shaft rotates 90 degrees.

Electric actuators for gearboxes are typically selected with a torque higher than the gearbox’s input torque (about 50%). The example above indicates that an actuator with about 50 newtons meters of torque should be considered.

The number of input revolutions of gearboxes is usually listed in catalogs. Gearbox catalogs specify the flange type according to ISO5211.

There are many countries and brands that produce multi-turn electric actuators. Here are some of the most popular electric actuators, each used in a different industry: