In general, a damper motor is a type of air flow blocker whose task is to open and close or adjust and control the amount of air flow passing through a path such as the air intake of the burner or even inside the duct and chimney, etc.

The burner air damper motor is responsible for adjusting the amount of air entering the burner. This action in the burners before the formation of the flame is the task of cleaning the primary dust inside the combustion chamber by resetting the air damper opening rate by the damper motor and the combination of the appropriate amount of air and fuel (gas and diesel) causes the formation of flame and combustion.

The most common use of burners is in engine houses and it is considered one of the main equipments of the engine house. For the correct operation of the burner, three very important factors, namely air, fuel and spark, must be provided, and if one of these factors is absent, the burner cannot work.

It should be noted that in single-stage low-capacity burners that have a gas electric valve or a diesel solenoid valve, the amount of air entering the burner is adjusted manually by the damper jack, and the damper motor or servo motor is not used. .

Installing dampers in environments such as tunnels, subway networks and in underground industries is mandatory and necessary. Heavy industrial dampers are also used in petrochemical, oil, gas, etc. industries.

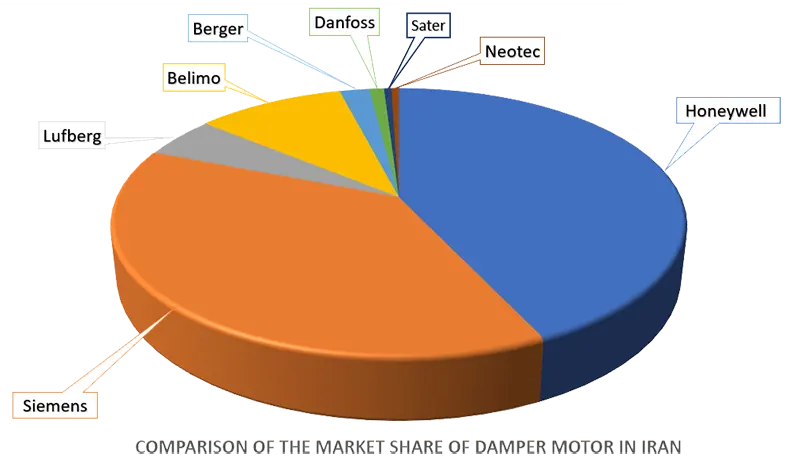

According to the surveys, Honeywell damper motor has one of the largest shares in the Iranian market. In fact, most of the engine dampers used in Iran are of the Honeywell brand. This motor brand offers dampers with different specifications and structures under various series and models. Although they all have the same function, the wiring diagram and how to set them up are different:

Lks 310-22 Conktron model is one of the most widely used damper motors, which is one of the most popular models in the market in terms of production quality, wiring diagram and price. Honeywell burner damper motor is used in gas burners, air valves and oil burners. The function of this damper electric actuator is gradual (modulation), which has high performance accuracy. The electric current supporting this damper motor is 220 volts and its frequency is in the range of 50 to 60 Hz.

This damper electric actuator has a 90-degree rotating course and is made in Western Europe. One of the unique features of Honeywell Lks series damper motors is the ability to rotate in both left-handed and right-handed ways (clockwise or counter-clockwise). The approximate start-up and movement time (Run Time) is between 3.5 and 30 seconds. The torque power of the Lks310 Honeywell damper motor is 15 Nm and its security protection class is Ip54. The presence of auxiliary switches is another feature of this damper actuator and its shaft length is 5 mm.

After the Honeywell damper motor, the Siemens damper motor is on the lower floor, but this damper motor has a higher price than the Honeywell damper motor, and they have different models with voltage and ampere input signals from 2N to 35Nm. Siemens damper motor products are very diverse, some of the most used ones are:

Siemens SQN series damper motor is another type of commonly used damper motor for burners. This series of dampers is made in 23 types with different features. The torque power of this damper motor is from -32 to +70 degrees Celsius and its body is highly resistant to environmental changes.

This brand, which is currently considered one of the most well-known brands in the world, is used in wide areas of the industry such as: Telecommunication equipment, household appliances, industrial automation, fire alarm and extinguishing systems, control equipment, and also the production of all kinds of trains have an impressive and extensive activity.

The history of the presence of the Siemens agency in Iran goes back to more than 150 years, so that this brand is considered one of the highest quality brands available in most industrial and construction fields in our country.