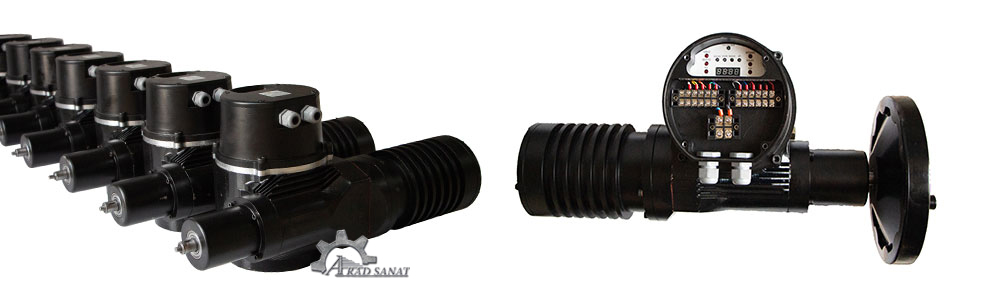

An electric actuator uses magnetic force and electricity, and is controlled by remote control. The importance of these components can be seen in industrial and automatic machines.

In contrast to manual and mechanical valves, electric valves have a limited power for valve operation, so it is important to use this limited power wisely and efficiently.

There are two types of actuators for electric valves: solenoid motor and electric motor. Whenever a large passage is needed, an electric motor is used. Typically, these motors are used with gears or reduction gear boxes to open and close them.

An electric valve is a device that allows the flow or non-flow of liquids and gases to be controlled. Different sizes and applications are available for this device. In the hydraulic industry, solenoid valves are very common.

Timers, micro switches, and other elements of the command circuit that we have are used to command it to open and close. Metal is the material used for this industrial piece.

The valve controls the flow of fluid inside the system circuit by opening and closing. Depending on the type of work, these valves work differently.

The electric valve has many uses; from houses to factories, agricultural land to industrial automation. Generally, these valves are used for liquids such as oil, water, or chemicals. As a result of its high usage, electric valves are in high demand in the market.

There are different types of electric valves, such as:

Each of them has its own use. A motorized electric valve is preferable in some cases when any of these electric valves can be used. Due to its movement mechanism, motorized electric valves usually have a much lifespan.

In the solenoid type, there is a linear motion. Electrical power is converted into mechanical power. A coil-and-iron core piece is used for all of this. This method forms the magnetic field when the electric current is activated. The solenoid valve, however, has several disadvantages:

There are no disadvantages to motorized electric valves. Typically, solenoid electric valves are manufactured in sizes up to 4 inches, whereas motorized solenoid valves come in a variety of sizes.

Additionally, pneumatic electric valves have many limitations due to their constant need for high-pressure air flow, high wear and tear of internal parts, the absence of a handwheel and the option to manually open and close the valve. A motorized electric valve does not have these limitations.

A valve can get stuck if you apply too much pressure when opening or closing it. When the applied pressure exceeds the tolerance of the selected valve, the valve is severely damaged and has inappropriate effects on the system. There is a risk of burning the bobbin or damaging the power supply if you use the wrong power supply.

Using a valve designed for intermittent use uniformly will damage it. Be sure to get as much information about the electric valves as possible. Always get the valve or actuator information sheet and catalog from the dealer.

Arad Sanat Company has specialized in electric actuators for the energy, water, oil and gas sectors, as well as the industrial sector, since 2016.